Tired of paying premium prices for mediocre seat covers? Discover how bypassing intermediaries unlocks superior quality at true factory costs.

Sourcing directly from OEM manufacturers eliminates middleman markups while ensuring quality through automated production, virgin materials, and strict quality control systems. Prioritize suppliers with mechanical quality checks and transparent pricing structures.

While low prices attract buyers temporarily, lasting partnerships require examining what hides behind those numbers. Let’s break down key factors every serious buyer must evaluate.

What is the best brand of car seat covers?

Brand names often mean paying 200-400% markup. Should you follow the crowd or seek better value?

The "best" brand depends on your priority: established labels offer recognition, while OEM suppliers provide equal/better quality at 60-70% lower costs through direct pricing models.

Three critical factors redefine "best brand" in seat cover sourcing:

Materials Matter: Virgin vs Recycled

| Metric | Virgin Materials | Recycled Materials |

|---|---|---|

| Durability | 8-10 years | 3-5 years |

| Color Fade | Resistant | Fades in 6 months |

| Safety | Non-toxic | VOC emissions |

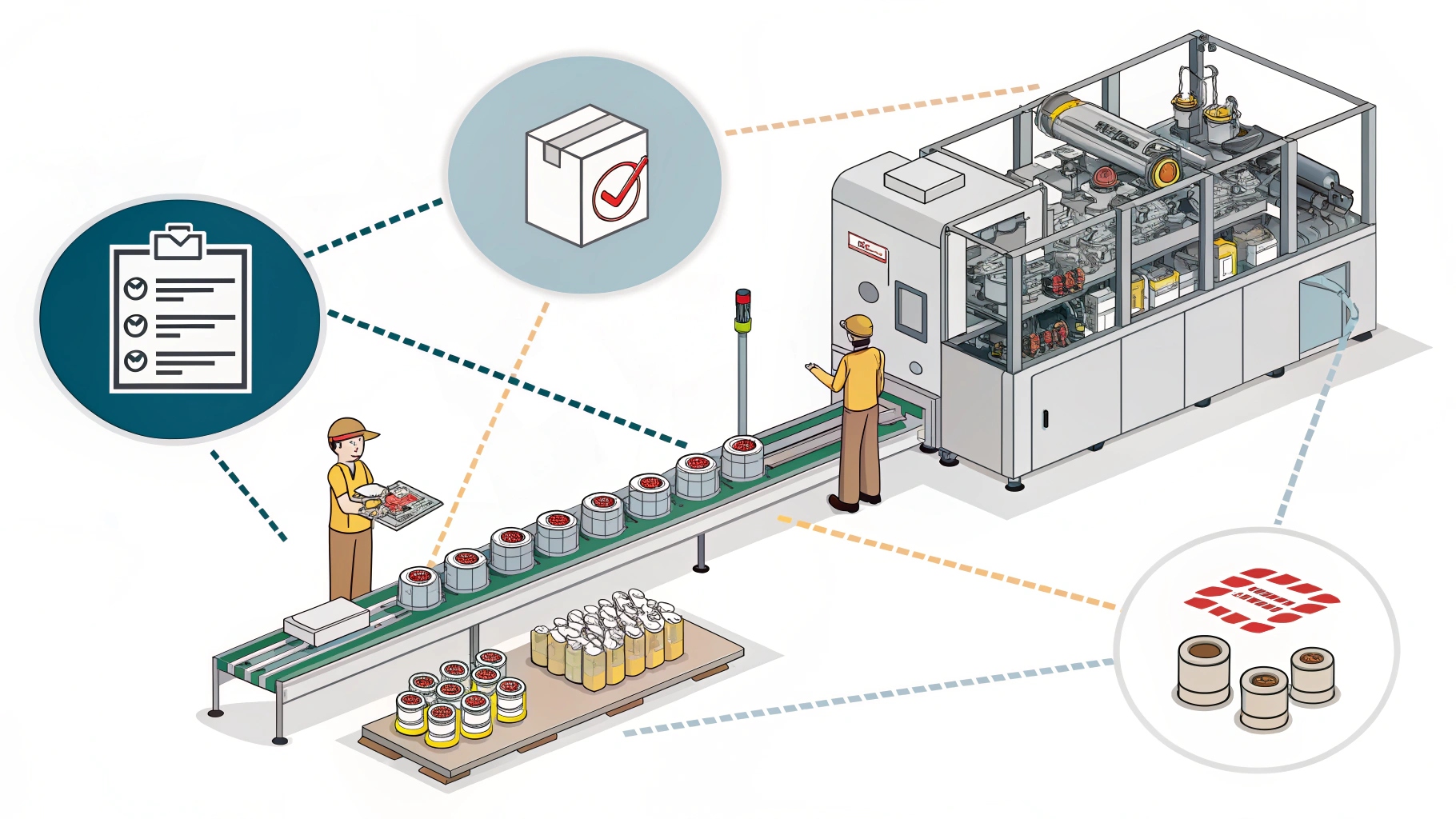

Automated production lines in our factory process 15,000 seat covers weekly using 320-360gsm PVC blends. Over 78% buyers switching to OEM partners report fewer customer complaints.

Quality Assurance Systems1

- Laser-guided cutting machines (0.2mm precision)

- Triple inspection points: raw material, mid-production, final packaging

- Batch testing certificates for tear resistance (ASTM D412)

ERP Integration

Real-time production tracking reduces lead times from 45 to 18 days versus traditional brands.

What is OEM seat covers?

Think OEM means "cheap copies"? Time to rethink this outdated assumption.

OEM seat covers are custom-made products manufactured to your exact specifications – materials, stitching patterns, logo placement – without brand licensing fees.

OEM manufacturing solves three core buyer challenges:

Design Flexibility

| Traditional Buying | OEM Solution | |

|---|---|---|

| Minimum Order | 500+ units | 200 units |

| Color Options | 6 standard | 25+ Pantone choices |

| Logo Options | None | Embroidery/printing |

Quality Control Process

- Raw material checks: Verify density (1.3-1.4g/cm³) and flexibility (-20℃ to 80℃ tests)

- Computerized stitching: 12 stitches per inch vs industry standard 8

- Final inspection: 100% leak testing for waterproof models

Cost Breakdown Example

- Branded covers: $28/unit (retail)

- Middleman price: $19/unit

- OEM direct: $12.50/unit (including custom tooling)

How big is the seat cover market?

Is this a shrinking niche or booming opportunity? The numbers surprise most buyers.

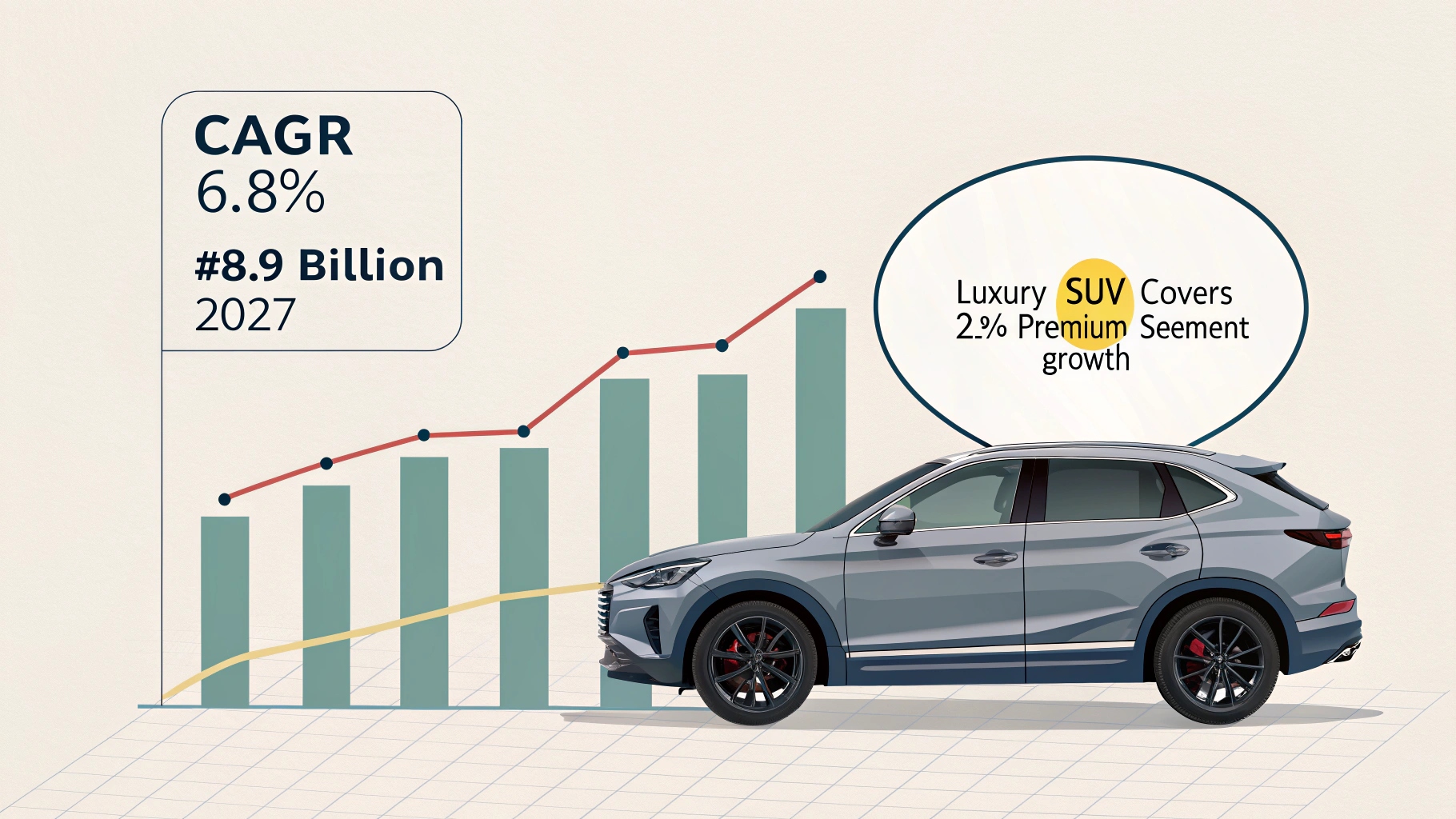

The global car seat cover market grows at 6.8% CAGR, reaching $8.9 billion by 2027. Luxury SUV covers drive 22% of premium segment growth.

Regional and material trends shape sourcing strategies:

Market Segmentation

| Region | Market Share | Growth Rate |

|---|---|---|

| Asia-Pacific | 38% | 8.1% |

| North America | 29% | 5.7% |

| Europe | 25% | 4.9% |

Premium leatherette covers now occupy 18% of B2B orders, up from 9% in 2019. Our factory’s advanced grain-pressing machines achieve genuine leather texture without animal products.

Emerging Opportunities

- Airbag-compatible designs: 34% demand increase since 2021

- Anti-microbial fabrics: Required in 92% of medical fleet orders

- Eco-friendly materials: 70% European buyers demand OEKO-TEX certification

How are car seats manufactured?

What separates factory-direct quality from marketplace rollouts? Precision engineering.

Modern manufacturing combines laser cutting (0.1mm accuracy), RFID tracking, and triple-stage QC to produce 400-600 covers daily per production line.

Our 18-step production flow ensures consistency:

Key Production Stages

| Stage | Technology Used | Quality Checkpoint |

|---|---|---|

| Material Prep | ISO 9001-certified mills | Thickness (0.8±0.05mm) |

| Cutting | CNC laser systems | Edge smoothness |

| Sewing | JUKI DDL-9000 machines | Stitch density check |

| Final Assembly | Heat sealing presses | Waterproofness testing |

Automated systems detect defects 47% more effectively than human-only checks. Our production lines achieve <0.8% defect rate versus industry average 3-5%.

Labor costs account for only 12% versus 55% in manual workshops, allowing us to maintain 18-24% margins while delivering premium quality.

Which material is best for seat covers?

Leather? Fabric? The optimal choice isn’t what most retailers push.

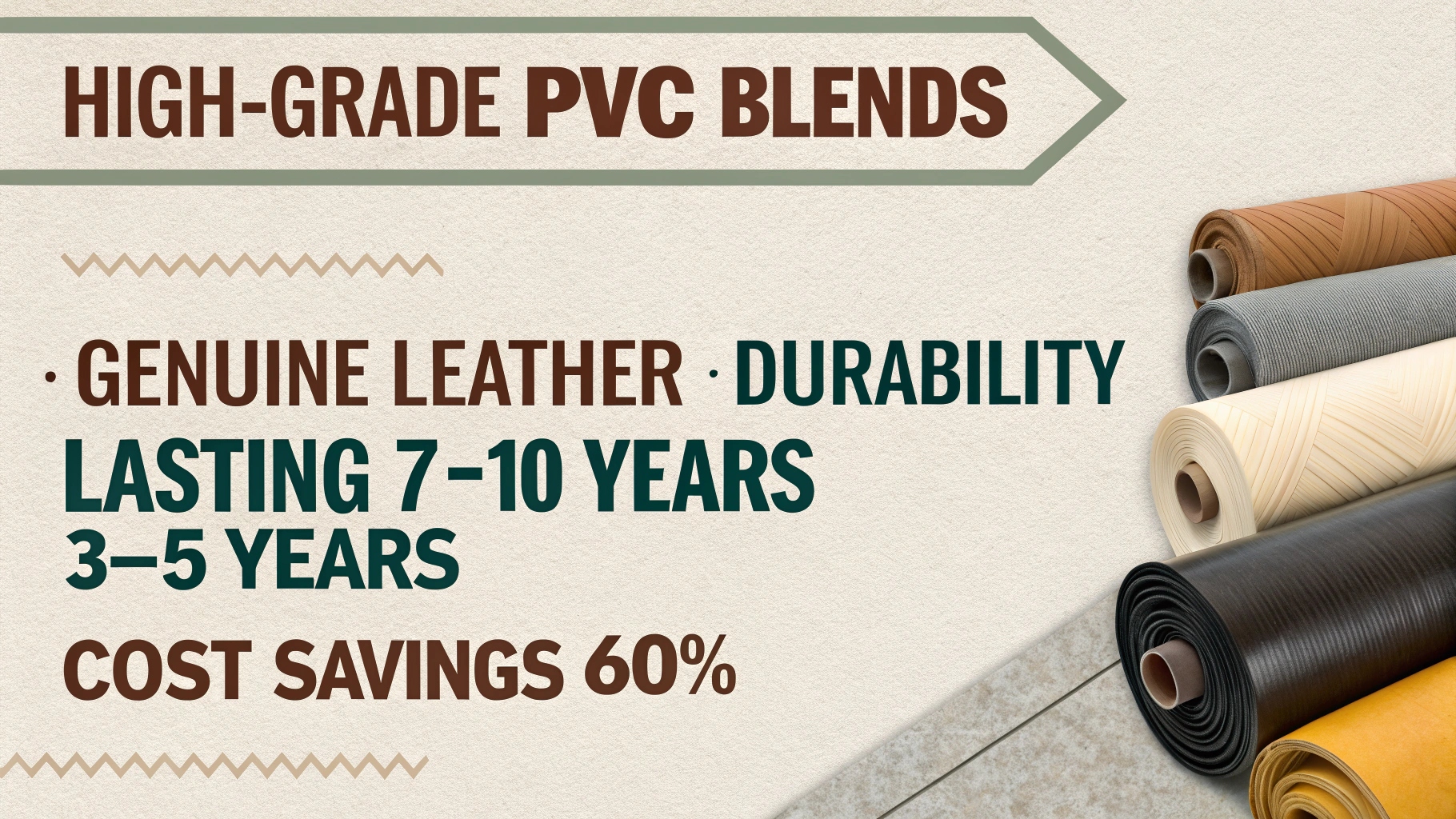

High-grade PVC blends outperform genuine leather in durability (7-10 years vs 3-5 years) and cost (60% savings), making them the practical choice for commercial fleets.

Evaluate materials through real-world metrics:

Performance Comparison

| Material | Cost/unit | Cleaning Time | UV Resistance |

|---|---|---|---|

| Leather | $45 | 15 mins | Moderate |

| Fabric | $22 | 25 mins | Low |

| PVC Blend | $16 | 5 mins | High |

Our proprietary PVC formula (60% polymer, 28% plasticizer, 12% stabilizers) withstands 50,000 abrasion cycles (ISO 5470-1). Over 90% of taxi operators using our covers report 2+ year replacement cycles.

Eco-friendly developments: New 35% plant-based polymers reduce carbon footprint by 18% versus traditional PVC, meeting EU REACH standards.

Conclusion

Factory-direct sourcing delivers value beyond price tags – consistent quality, custom solutions, and supply chain transparency that middlemen can’t match.

-

Learn about the latest quality assurance practices that ensure durability and customer satisfaction in seat covers. ↩